Tungsten heavy alloys (WHAs) are often used instead of pure tungsten because they have a significantly higher density and improved mechanical properties. Pure tungsten is relatively brittle and has a low density compared to other metals, which makes it difficult to work with and limits its applications.

WHAs are made by alloying tungsten with other metals, such as nickel, iron, and cobalt, which increases its ductility, toughness, and strength. The added metals also increase the density, which makes it ideal for applications where high density and weight are required.

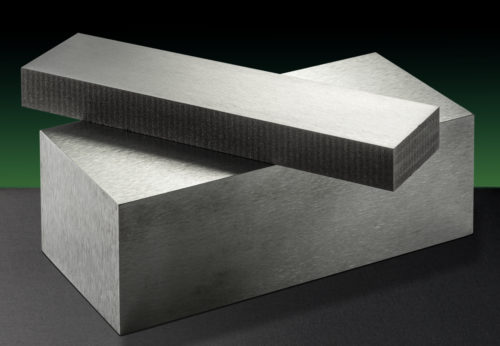

Tungsten alloys are primarily used in aerospace, military, and medical applications, as well as in sports equipment and industrial machinery. They are often used to make counterweights, radiation shielding, and other high-density components. They also have potential use in the field of nuclear medicine and radiation therapy as a radiation shield or in brachytherapy as sources.

There are several types of tungsten heavy alloys which Admat supplies, each with unique properties and uses. Some examples include:

- W-Ni-Fe: This is the most common type of tungsten heavy alloy and is composed of tungsten, nickel, and iron. It has a high density and is used for applications such as radiation shielding and balancing weights.

- W-Ni-Cu: This alloy has a higher thermal conductivity than W-Ni-Fe and is used in applications that require good thermal conductivity such as heat exchangers and electrical contacts.

- W-Ni-Mo: This alloy has excellent wear resistance and is used in applications that require wear resistance such as bearings and seal rings.

It’s important to note that the composition and properties of tungsten heavy alloys can be tailored to specific application needs by adjusting the ratio of the elements that are present.

In summary, Tungsten heavy alloys are used instead of pure tungsten because they have a higher density, improved mechanical properties and increased ductility, toughness, and strength.