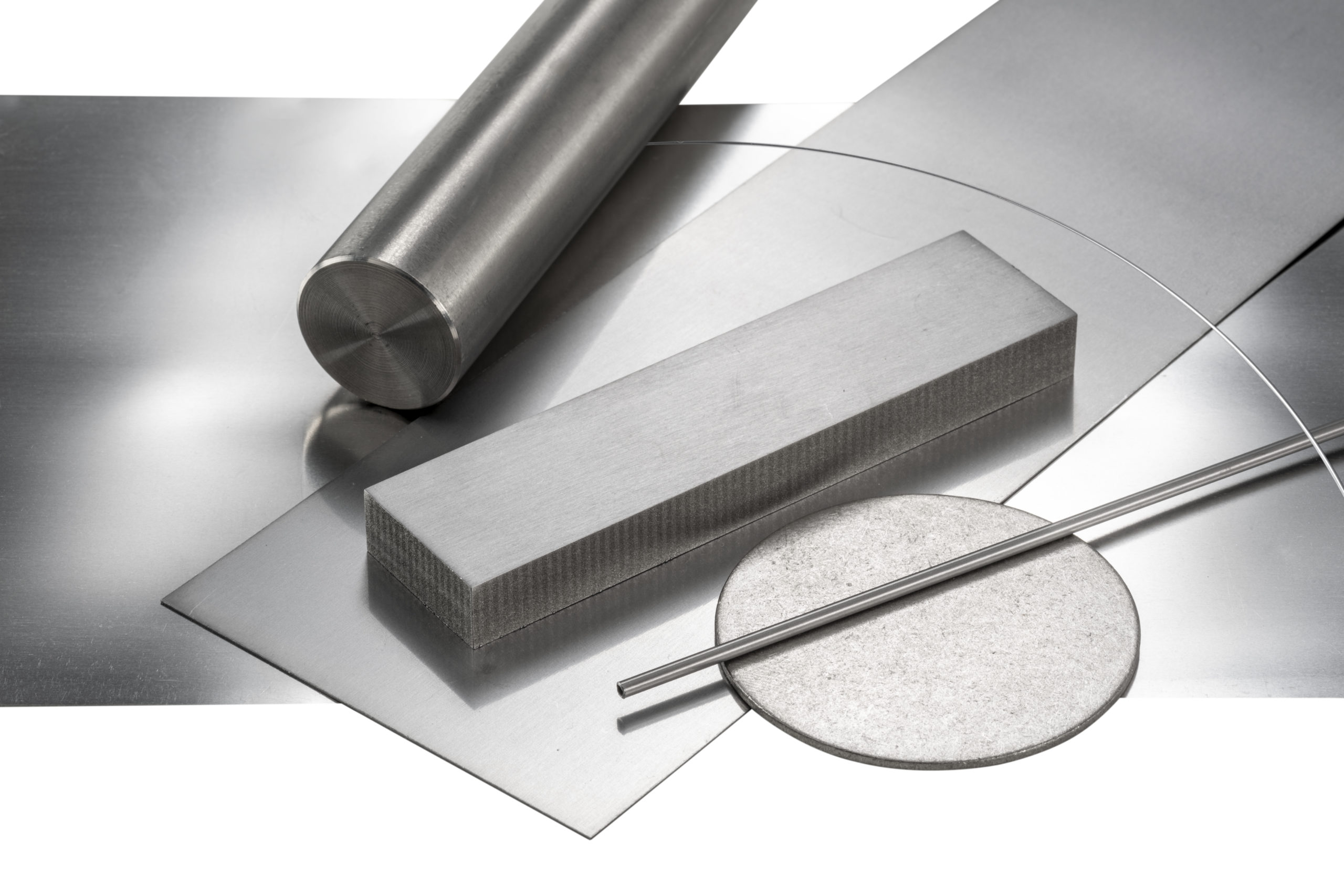

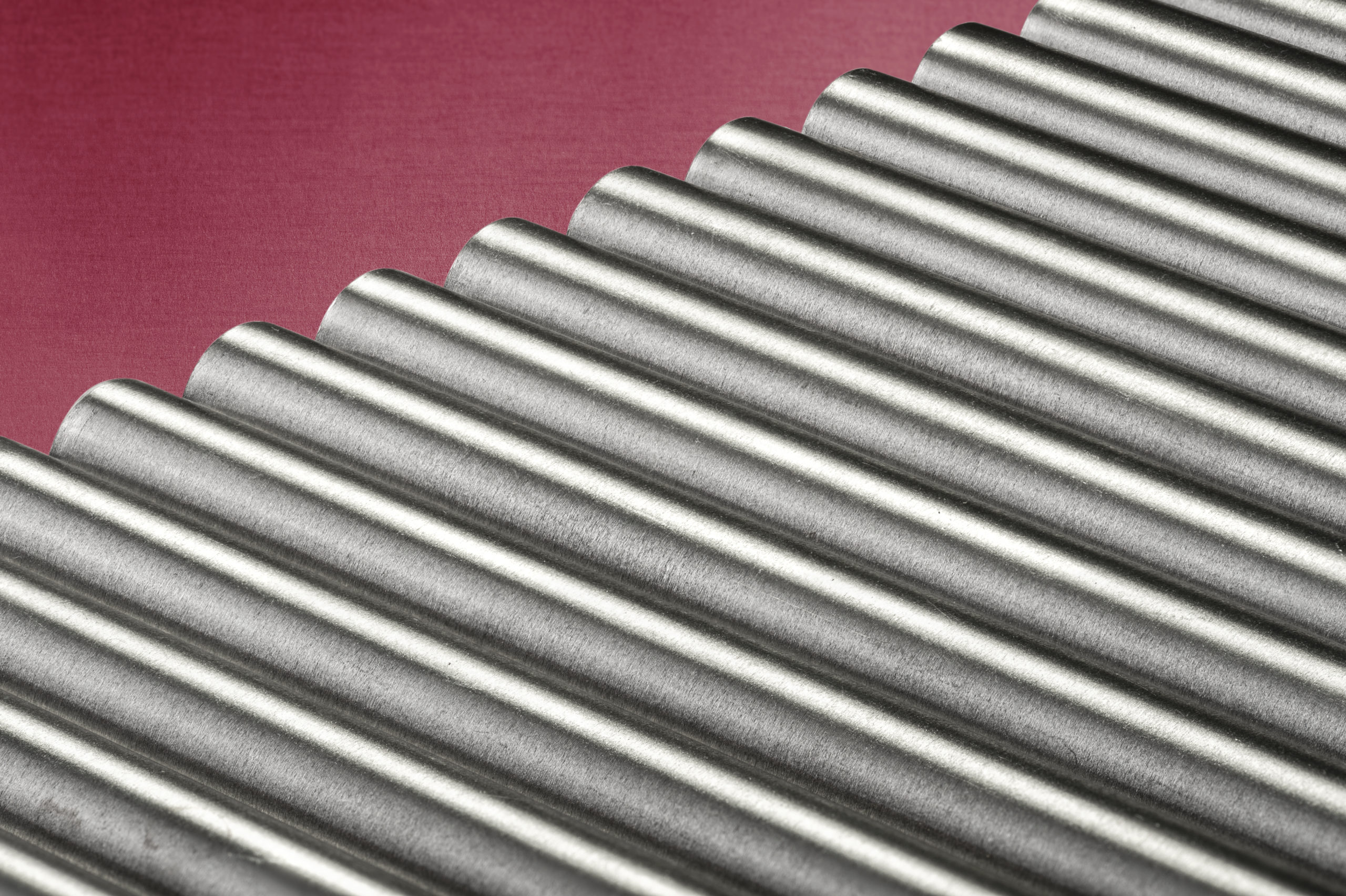

Sheet and Plate

Elevate your projects with exceptional performance. Admat Inc. provides premium tungsten

sheet and plate, renowned for their high density, superior radiation absorption, and unmatched

strength. Whether you need shielding for extreme environments or components for high-

temperature applications, Admat delivers the perfect tungsten solution.