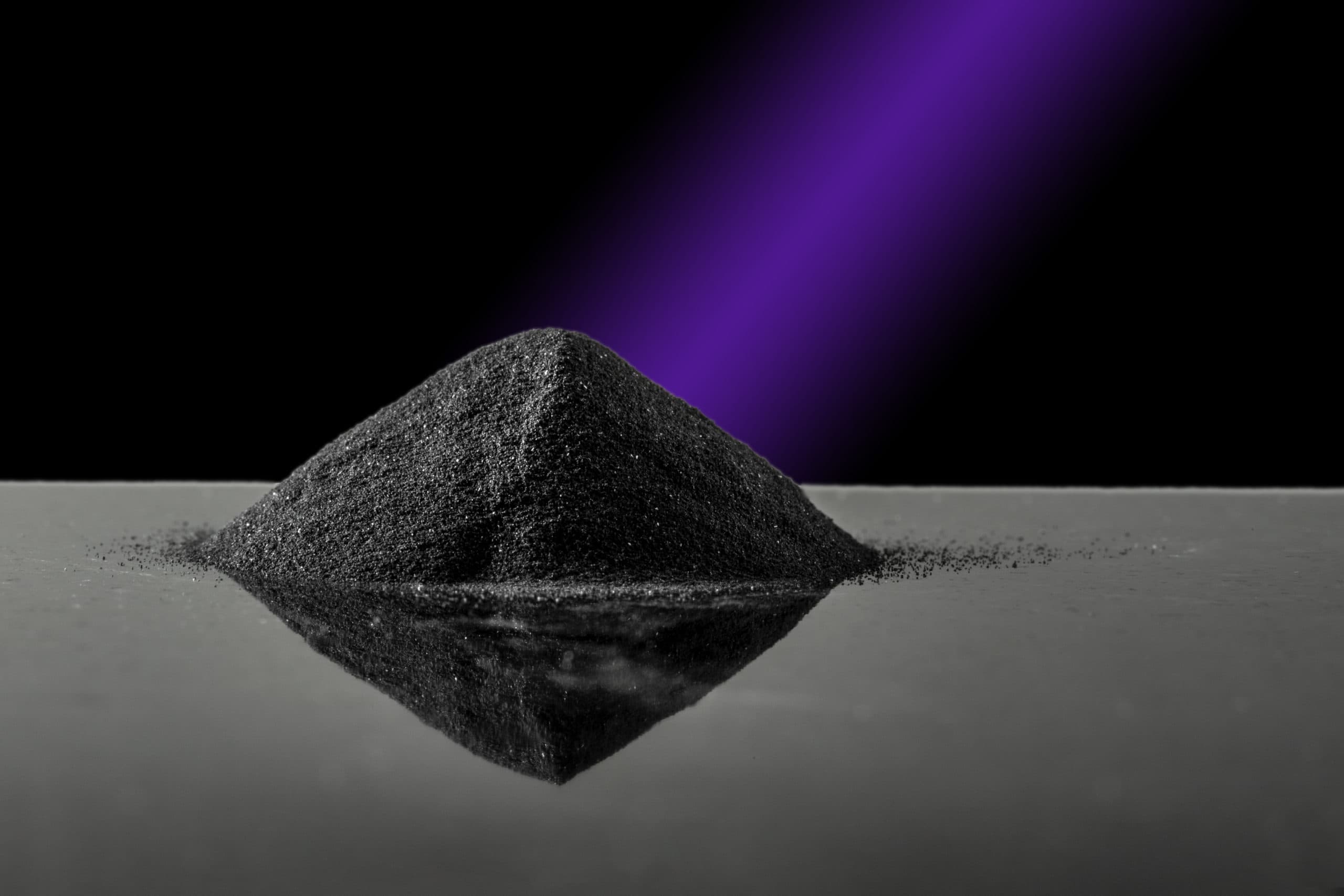

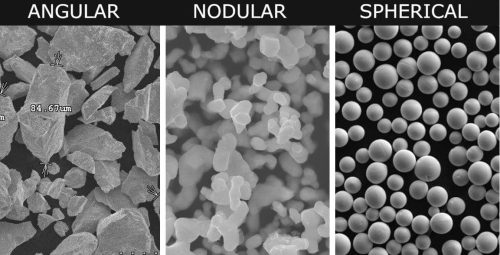

Tantalum Powder is a grayish-black or dark gray metallic powder. Tantalum is a rare, hard, and corrosion-resistant transition metal that is known for its high melting point, excellent conductivity, and ability to withstand extreme temperatures and chemical environments.. It is also biocompatible. There are three primary types of tantalum powder: nodular, angular, and spherical. Each type has a distinct physical shape and is derived from a unique process.

- Nodular Tantalum Powder is made by molten sodium reduction of tantalum salt or solid magnesium reduction of tantalum (V) oxide. The powder is aggregates of primarily particles and pores. It has relatively low density and high surface area.

- Angular Tantalum Powder is made by hydride and crush of a solid ingot (either electron beam or vacuum arc melted), and de-hydride. The particle looks angular and is non-aggregated; the bulk density is typically higher than that of nodular.

- Spherical Tantalum Powder is produced through the spherization of the aforementioned powder or wire materials. This manufacturing process results in particles that possess a nearly spherical shape, featuring a smooth surface and a narrow distribution of particle sizes. These characteristics play a pivotal role in facilitating exceptional flow and enabling dense packing, making them ideal for 3-D printing.

Tantalum powder has various applications, including:

- Tantalum capacitors: High dielectric constant and long term stability make tantalum powder an excellent material for electrolytical capacitors. The powder is pressed into a porous pellet, sintered to improve particle bonding, electrolytically anodized to form a pentoxide (V) dielectric layer, coated with a cathode electrolyte, and encaged. This is the largest use of tantalum.

- Tantalum mill products: The powder is pressed to a bar and sintered at high temperature to achieve a density as close to the true density as possible. The sintered bar is then processed into wires, rods, sheets, strips, and tubes, etc. Mill products made from sintered bars have a finer and ore uniform grain structure, better drawability, and can sustain higher temperatures than those derived from melted bars or ingots.

- New generation of tantalum sputtering targets: The target is produced by pressing the powder in pure form or mixed with other metal powders, sintering it to near-true density, and shaping it to a desirable geometry. The target has a uniform, fine grain structure and better quality than that made from traditional electron beam melted ingot.

- High temperature or corrosive resistant coating on another metal.

- 3-D printing: This is a new technology which builds the finished part one layer at a time. The process requires a powder with well-defined particle and size distribution to eliminate voids in the printing process. Spherical powder is particularly important for this application.

- Medical porous tantalum implant materials. Tantalum powder’s high sintering strength, uniform porous pore size, stable mechanical properties, high purity, and good biocompatibility make it an ideal material for human bones.

- Alloy additives.

Admat offers a wide range of tantalum powders with a purity a purity up to 99.995%.

For Spherical Tantalum Powder, the particle size options are:

- Particle size: 15-45μm (90% will fall in this range)

- Particle size: 45μm-105μm (90% will fall in this range)

- Customsizes are also available

Nodular and Angular Tantalum Powders are available in sizes such as

- -100 mesh (-150 microns)

- -325 mesh (-45 microns)

- -170/+325 mesh (-90/+45 microns)

- – 5 micrometers

- Custom sizes are also available.

Admat also offers a broad selection of capacitor grade tantalum powder, which includes different levels of capacitance, bulk density, sieve size range, and purity, as listed below:

Ta Powder purities include:

- Commercially pure

- 3N (99.9%)

- 3N5 (99.95%)

- 4N (99.99%)

Whether you’re manufacturing capacitors, sputtering targets, mill products, or 3D printed parts, Admat offers top-notch tantalum powders tailored to your specific requirements. Our extensive range of customizable options ensures that we can meet your unique needs with high-quality products. Our team of dedicated experts is committed to delivering exceptional customer service and technical support, guaranteeing that you receive the best possible product for your applications. Reach out to us today to discover more about our tantalum powder offerings and the comprehensive services we provide.