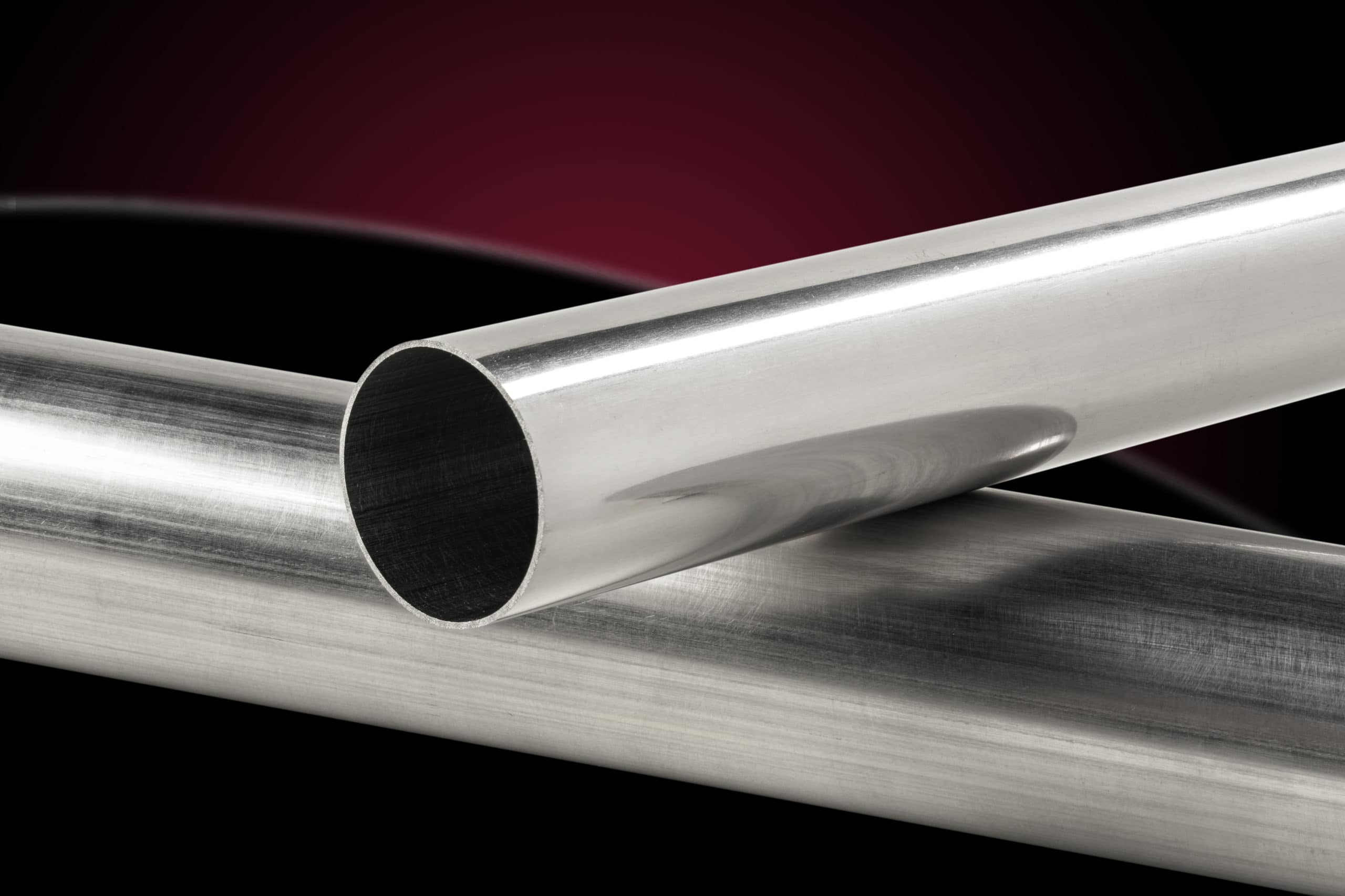

Tantalum Tube

Admat provides our customers superior tantalum and tantalum alloy seamless tubes. Less likely to fail than typical welded tubing, our process starts by piercing large diameter billets and forging the tubes down to your required dimensions. This eliminates weak spots in the products that could fail due to cracking, holes or tearing. Additional we can perform an eddy current test to detect leaks and pressure test the tubes to ensure there are no leaks.

In general, tantalum has excellent corrosion resistance and is often used in chemical processing equipment. To enhance the performance of the metal, Admat recommends using our seamless tantalum 2.5% tungsten tubing.

A wide variety of diameters and wall thicknesses are available. The typical specification is ASTM B521 R05200 for pure tantalum and ASTM B521 R05252 for tantalum 2.5% tungsten.

Size Capabilities

for Niobium Seamless Tubes

- O.D. — .039″ to 6″

- Wall — .008″ to .200″

- Length — 39′ (12 meters ) Max

- Certain wall thicknesses and lengths not available with all diameters.

Common Specifications

- ASTM B521 R05200

» Electron Beam Melted (unalloyed) - ASTM B521 R05400

» Powder Metallurgy Grade (unalloyed) - ASTM B521 R05252

» Tantalum 2.5% Tungsten Alloy - ASTM B521 R02555

» Tantalum 10% Tungsten Alloy - ASTM B521 R05240

» Tantalum 40% Niobium Alloy

Available Alloys:

- Tantalum

- Tantalum 2.5% Tungsten

- Tantalum 7.5% Tungsten

- Tantalum 10% Tungsten

- Furnace Grade Tantalum

- Tantalum 40% Niobium